the Beacon

-

what it is

The Beacon transforms the traditional trumpet into a responsive hyperinstrument that exists at the intersection of acoustic tradition and digital potential. Motion sensors track every gesture and movement, feeding data to custom MaxMSP patches that process the live sound in real-time, creating a new instrument that is performed in multiple dimensions.

-

how it works

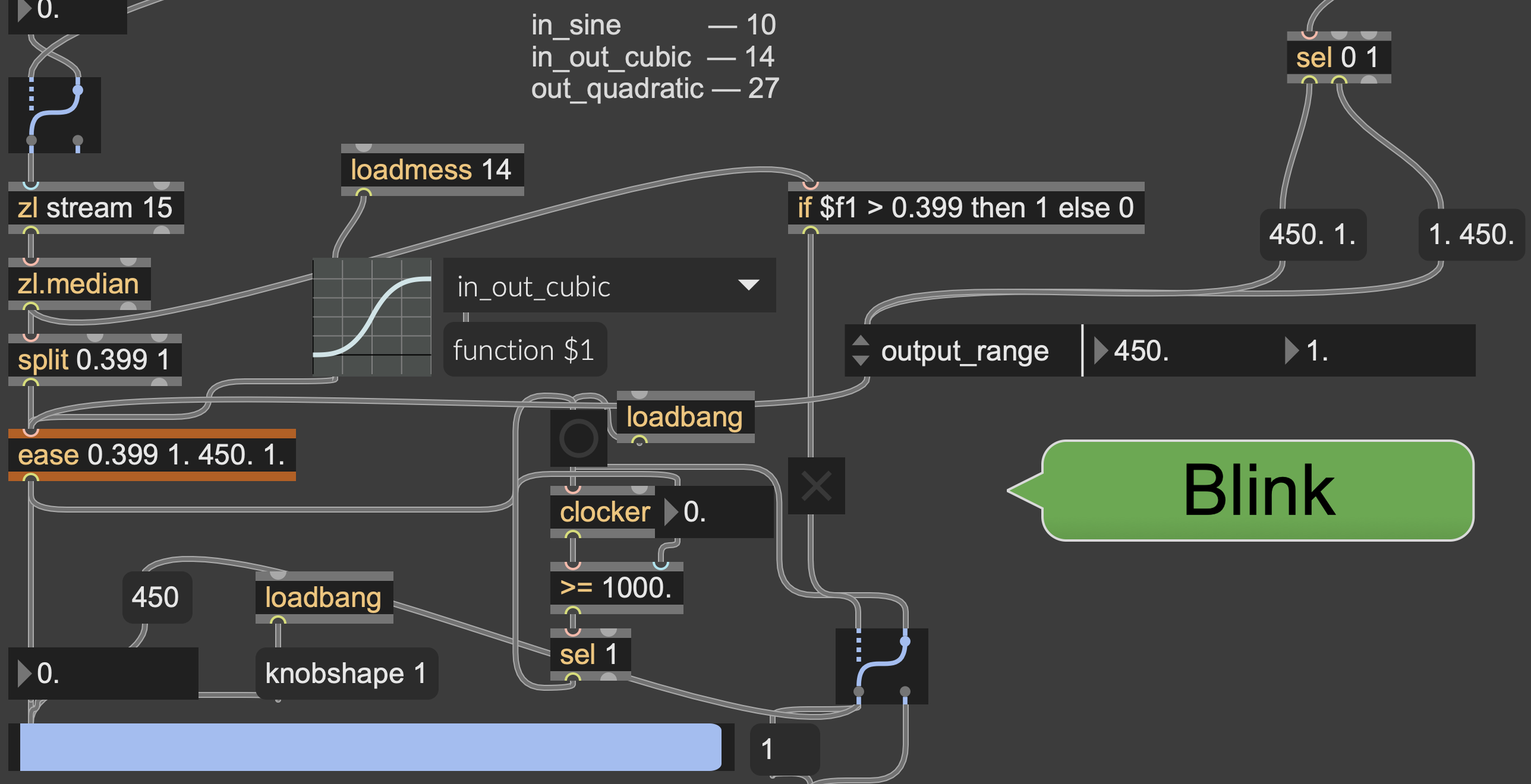

A microcontroller board captures motion, direction, and acceleration data from sensors mounted in custom 3D-printed enclosures, while light and color sensors detect ambient conditions and color-coded feedback. This sensory data flows wirelessly via Bluetooth Low Energy to MaxMSP, where it controls pitch shifting, delay loops, and other audio textures based on the trumpet's position, movement, and surrounding light. Raising the horn skyward transforms the sound. Using a traditional plunger mute triggers the proximity sensor, setting off different sonic textures. The instrument becomes an extension of both body and intention.

-

where it's going

Each update of the Beacon pushes further into uncharted territory. In-progress versions are incorporating reactive LED lighting, pressure-sensitive valve sensors, live video generation through Jitter and TouchDesigner, spatial staged choreographies, and wearable companion tech-clothing. The Beacon expands what a trumpet can be when tradition meets technology and when the boundaries between instrument, performer, and space dissolve.

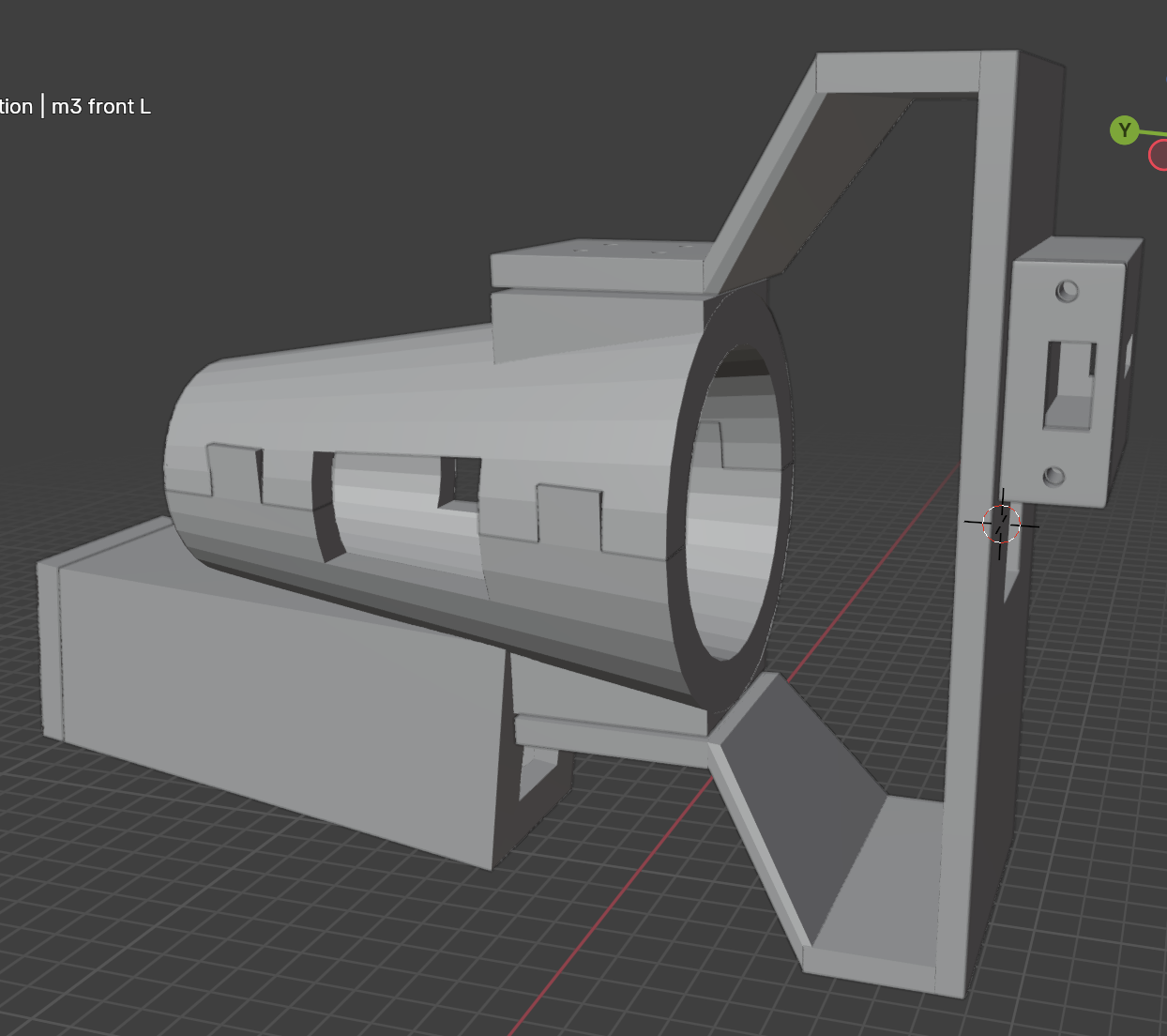

3d scanning

The first step in building the Beacon required creating custom enclosures that could seamlessly integrate with the trumpet's curves while protecting the delicate sensors inside. A trumpet (with the pickup mute in the bell) was 3D scanned from every angle (seen to the side here), capturing its complex geometry in digital space. These scans became the foundation for designing housings that attach to the instrument without interfering with performance.

3d printing

Transforming digital models into physical reality meant adapting to the quirks of 3D printers. Through countless iterations, each rework brought closer into reality the first complete prototype, balancing minimal design with maximum durability.

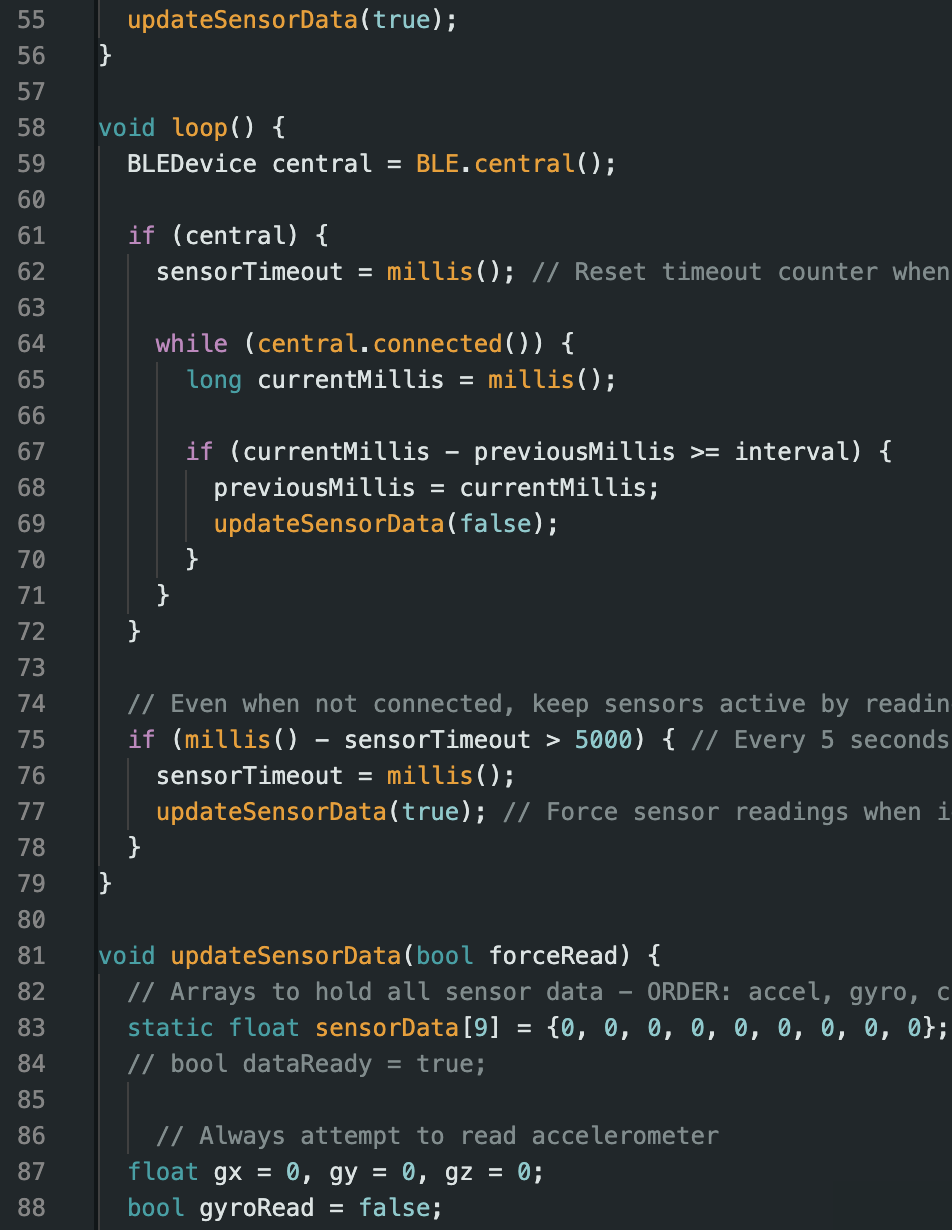

software

The Beacon lives across multiple software environments. Blender shapes the 3D world where enclosures are sculpted to fit perfectly against brass and plastic curves. Arduino captures raw sensor readings before shipping it off via Bluetooth Low Energy (BLE) to MaxMSP, which serves as the central nervous system, receiving sensor data and transforming it through real-time audio processing.

call for collaborators

The Beacon thrives in conversation with other experimental voices. Recent performances have explored its interactions with modular synthesizer, processed brass has been woven through the microtonal world of the setar, and it has found a comfortable fit within free-improvising ensembles. There may be something brewing with robotics soon as well.

I am drawn to any collaboration that pushes both the technology and the music into new territory. If you're working at the edges of your own practice or curious about the technology involved in the Beacon, don’t hesitate to reach out!